Designed for top-quality production requirements with the best energy performance (<800kcal/kg)

The use of microporous insulation materials, the light-weight crown in cordierite that guarantees thermal inertia, the light-weight materials, and the fiber used for the cars are all choices pinpointed to minimize thermal dispersions. Differentiated adjustment over and under the load means you only use the heat where it is needed.

The consumption of this type of kiln is extremely low. The average production requirements and standard firing cycles are less than 800 kcal/kg net, thanks to the energy recovery solutions available from our product range.

energy saving - innovation - user friendliness

Energy Saving

•TITANIUM® TECHNOLOGY

•-30% - Lowest Energy Consumption Kilns In The Market

•Reduced Pullutants Emissions CO, CO2 and NOx

User-friendliness

•Increased flexibility on product mix

•Higher temperature uniformity

•Higher production quality

4.0 Industry – bt-TUTOR ready

Details

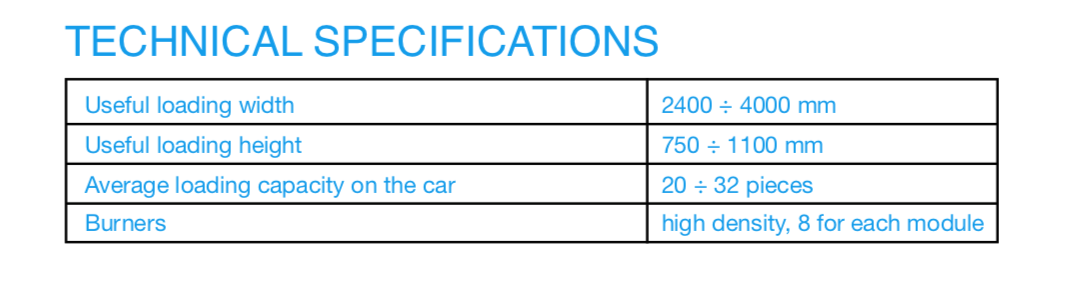

The tunnel kilns measure between 40 and 185 meters long, the cars are 2400 / 2750 / 3200 / 3600 / 4000 mm wide, and the loading heights range from 800 to 1100 mm.

Innovation

•Increased first-choice rate.

•Perfect white balance control.

•Quick re-firing.

Pressurization

All the pressurized air pipes are made of stainless steel type AISI 304. All the fans have double filters to be disassembled and cleaned without ever putting the pipes into direct contact with the external environment.